- Top

- Turnpoint Media

- Technology

- What is the AEC-Q100 standard for automotive electronic components?

テクノロジー

What is the AEC-Q100 standard for automotive electronic components?

Need help with your job search?

Consultation

- I don't know if there is a job that fits my criteria

- I don't have time to look for jobs.

- I want to start thinking about career planning.

Turnpoint Consulting is a recruitment agency specializing in the automotive and mobility industry. Our industry experts will support you in your career.

Table of Contents

What is AEC-Q100?

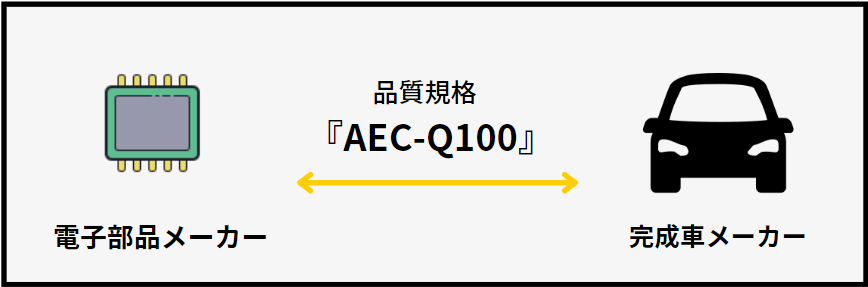

AEC-Q100 is a quality standard to ensure the reliability of automotive electronic components. This standard is intended for electronic component manufacturers to meet the requirements for automotive electronic components. It then specifies various test requirements and demand criteria.

Specifically, electronic component manufacturers manufacture automotive electronic components in accordance with this standard. The automobile manufacturer then evaluates and inspects the electronic components in accordance with this standard. In other words, both the electronic component manufacturer and the automobile manufacturer must understand this standard when it comes to the manufacture and use of automotive electronic components. In other words, it is the universal language of quality.

Background of the AEC-Q100

Reliability and sophistication of automotive electronic components

The background for the emergence of this standard is the rapid development of the automotive industry as well as the increasing use of electronics in vehicles. Electronic components in vehicles are critical for safety and reliability. And especially as complex in-vehicle systems become more prevalent, those requirements are becoming increasingly important.

On the other hand, although conventional automotive electronic components only control basic functions in the vehicle, the internal environment of an automobile is more severe than usual, and high reliability has traditionally been required of automotive electronic components.

In recent years, however, many electronic components with more sophisticated functions, such as engine management, airbags, brake control, and driver assistance systems, have been adopted. In other words, automobiles are becoming more “electronic”. As a result, the reliability and safety of these components has become a more stringent requirement for the entire automotive industry.

Under these circumstances, AEC-Q100 was established as a quality standard for electronic components to improve safety and reliability in the automotive industry. This requires automakers and manufacturers of electronic components to meet higher standards, resulting in the production of safer and more reliable vehicles.

Country of origin and relationship with ISO

AEC-Q100 is a standard developed by the Society of Automotive Engineers, SAE International. This U.S.-based international professional association of automotive engineers contributes to the standardization of technology and the development of standards in the automotive industry.

And AEC-Q100 has been widely adopted by automakers and suppliers around the world, becoming part of the global quality standards in the increasingly internationalized automotive industry.

ISO (International Organization for Standardization) is an international standards organization that promotes standardization across a variety of industries worldwide. Standardization in the automotive industry is one part of this effort, and ISO has developed a variety of standards relevant to the industry.

For example, the ISO 9000 series is an international standard for quality management systems and applies to the automotive industry. ISO 26262 is also a standard for functional safety in the automotive industry, defining processes and requirements to ensure the safety of electronic and electrical systems in vehicles.

AEC-Q100 is positioned as one of the standards related to the automotive industry developed by ISO, but it is not directly recognized as an ISO standard. In other words, there is no “ISO 0000” standard. However, the AEC-Q100 standard has been widely adopted by the international automotive industry and is related to ISO’s standardization activities; when ISO develops a standard for standardization related to automobiles, it will be developed with reference to this AEC-Q100.

AEC-Q100 Features

In a word, “very strict”: AEC-Q100 is a very rigorous standard designed to ensure the reliability of electronic components in the automotive industry. In the automotive industry, vehicle safety and reliability are top priorities, which is why such a rigorous standard is necessary.

The AEC-Q100 standard includes a variety of stringent testing requirements, including temperature cycling tests, moisture heat resistance tests, and mechanical shock tests. And even these physical tests are more demanding than normal standards in AEC-Q100, because high quality standards and reliability are necessary to meet these requirements.

In the design phase, the IC must be designed reliably to meet the requirements of AEC-Q100, and in the manufacturing phase, appropriate manufacturing processes and quality control systems must be established and tested and verified to meet the AEC-Q100 criteria. testing and verification must be performed.

Therefore, it has detailed and detailed requirements such as “design criteria” at the design stage and “manufacturing criteria” for each manufacturing process of electronic components. In other words, AEC-Q100 is a standard for the entire manufacturing process of electronic components and not simply a standard for the product itself.

In other words, it does not matter how the final product is manufactured as long as it conforms to the standard, but rather that certain standards are established for each manufacturing process.

Importance of complying with AEC-Q100

Why do we need strict standards?

Automotive electronic components are designed to improve vehicle driving safety, comfort, and efficiency.These components must withstand harsh environmental conditions such as temperature fluctuations, vibration, humidity, and electromagnetic interference, and must be designed and manufactured to be more robust and reliable than typical electronic components.

In other words, it is “different” from general electronic components.

Given these and other special characteristics, AEC-Q100 is important to ensure the safety and reliability of electronic components in the automotive industry. It enables automakers and suppliers to produce safe, high-quality vehicles.

Advantages of the AEC-Q100

Again, compliance with the AEC-Q100 standard is very important in the automotive industry. In addition, compliance with the standard offers several advantages.

– Ensuring High Reliability and Safety

Compliance with AEC-Q100 standards ensures high reliability and safety of electronic components. This will improve the driving safety of automobiles and provide consumers with highly reliable products.

– Improved Quality Assurance and Quality Control

Meeting AEC-Q100 standards requires a rigorous quality control system. This improves product quality assurance and increases product reliability.

– Reliability as an Industry Standard

AEC-Q100 is recognized as an industry standard in the automotive industry, and compliance with this standard is important for automakers and suppliers to remain competitive in the marketplace.

– Improving Customer Satisfaction

Meeting AEC-Q100 standards improves customer satisfaction. Reliable products give customers a sense of security and can lead to increased brand value. It also serves as proof of high product quality.

AEC-Q100 is one of the most important standards in the automotive industry

The above is a brief look at AEC-Q100. As explained in the introduction, automobiles have become increasingly electronic in recent years. As a result, the reliability required for automotive electronic components is also increasing. To ensure a stable supply of such highly reliable electronic components, strict quality control is especially important, and AEC-Q100 is the standard for such advanced quality control and has become a worldwide standard.

The work of quality control in the implementation of AEC-Q100 is a modest task, but its importance is very high and it is a very fulfilling job. The demand for electronic components is increasing along with the progress of software in automobiles, and at the same time, the efficiency of such components must be improved. To adapt to this change, deepen your expertise and advance your career in the field of quality control. A rewarding path to contribute to the technology of the future awaits you.

There is an urgent need for human resources in this field in the automotive sector as well. If you are looking for jobs related to automotive semiconductors, please contact Turnpoint Consulting. About 80% of the jobs Turnpoint Consulting handles are private jobs. Therefore, we are able to introduce you to a large number of jobs with favorable conditions that are not posted on general job sites. We support your job change with our overwhelming knowledge of the industry and thorough interview preparation. Let Turnpoint Consulting help you find the right company for you.

Author: Fumitoshi Sato Supervisor: Turnpoint Consulting Media Team

We are a media team that provides useful information about changing jobs related to the automotive and mobility industry. For those who are thinking about changing jobs, we will provide information about the job market in the automotive and mobility industry and how to prepare for the selection process, and for corporate recruiters, we will provide information about the flow of human resources in this industry. Our goal is to help you by providing information about changing jobs and recruitment in the automotive and mobility industry.

Need help with your job search?

Consultation

- I don't know if there is a job that fits my criteria

- I don't have time to look for jobs.

- I want to start thinking about career planning.

Turnpoint Consulting is a recruitment agency specializing in the automotive and mobility industry. Our industry experts will support you in your career.

Related Articles

-

2025.06.21

Job Change x Trend News] Can’t Take My Eyes Off of You! Summary of the latest EV situation

-

2025.06.21

Gigacast is the key to EV manufacturing! Summary of companies introducing Gigacast

-

2025.06.20

Job Change x Trend News] By Manufacturer! Summary of the latest situation of self-driving cabs

Search by Industry

Consultation

Our expert team is dedicated to empowering your career change, crafting tailored career plans, and securing the best job opportunities in the automotive and mobility sectors.

- Top

- Turnpoint Media

- Technology

- What is the AEC-Q100 standard for automotive electronic components?